First Cobalt awards construction contract to Metso Outotec for its Canadian refinery

Mike Edwards

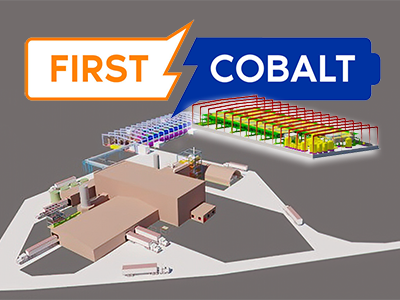

News First Cobalt Metso Outotec refinery video Rendering of Phase 1 of First Cobalt's refinery in Canada at time of commissioning in Q4 of 2022. Inset: 3D rendering of First Cobalt's new solvent extraction plant.

Rendering of Phase 1 of First Cobalt's refinery in Canada at time of commissioning in Q4 of 2022. Inset: 3D rendering of First Cobalt's new solvent extraction plant. First Cobalt Corp. of Toronto has awarded a contract to industry expert Metso Outotec for the design and manufacturing of solvent extraction cells as well as technical support for the layout of a new solvent extraction plant and its process control.

The solvent extraction contract is the largest and most important equipment package now under contract.

Metso Outotec of Helsinki, Finland, has provided similar equipment to other operational cobalt sulfate refineries, which is said to lower the execution risk for the company’s strategy of producing battery-grade cobalt sulfate.

Commissioning of Phase 1 of First Cobalt’s low-carbon hydrometallurgical refining strategy is scheduled for Q4 of 2022, targeting annual production of 25,000 tonnes of cobalt sulfate annually.

Once operational, First Cobalt’s refinery will be the only producer of battery-grade cobalt for the North American electric vehicle market, capable of supplying over 1 million vehicles per annum, responding to strong demand in the accelerating EV revolution.

Watch video demonstration of extraction plant construction and operation:

The contracted solution involves the latest advancements in solvent extraction in terms of modular design, process control and ease of installation and start up. The installation time of the modular mixer-settlers is evidenced to be 30 percent less than the conventional solvent extraction mixer-settlers used at other projects. In addition to the reduction in site install time, the footprint needed for the selected plant equipment is less than conventional solvent extraction equipment.

“We are happy to be moving forward with Metso Outotec, an industry-leading business partner,” explains Trent Mell, First Cobalt president and CEO.

“Their expertise and ability to deliver quality projects significantly de-risks our own. We move one step closer to becoming North America’s only provider of cobalt sulfate and we do not intend to stop there.

“Plans for our Canadian Battery Materials Park also include battery recycling, nickel sulfate production and a partnership with a battery precursor manufacturer.”

January 2021, First Cobalt secured long-term cobalt hydroxide feed arrangements with Glencore AG and IXM SA, a subsidiary of CMOC, to provide a total of 4,500 tonnes of contained cobalt per year to the First Cobalt Refinery commencing in Q4 of 2022. In March 2021, the company further de-risked the project by signing a flexible, long-term, offtake agreement with Stratton Metal Resources Limited for the sale of future cobalt sulfate production, with quantities determined by First Cobalt (subject to a minimum).

Negotiations with automakers and battery suppliers are ongoing, with a growing interest in sourcing battery material from North America.

Print this page