Wilden SafeGuard Remote Performance Monitoring and Alert System

The Wilden SafeGuard is the industry’s first AODD Internet of Things (IoT) enabled remote performance monitoring and alert solution. It is a true game-changer in optimizing AODD pump performance, reliability, cost of operation and maintenance. SafeGuard is an all-inclusive monitoring system that tracks, records and alerts customers to key AODD pump performance indicators at all times of operation via continuous Cloud connectivity as a way to address and prevent operational shortcomings that can result in costly pump failures.

Why is Pump Monitoring So Important?

Unexpected pump failures can be devastating for an operation, and could result in much larger issues, including the high cost of downtime, repairs, lost product and product cleanup. This makes monitoring and anticipating potential AODD failure conditions a critical consideration for facility operators.

|

|

|

|

Unexpected Pump Failure |

Product Leakage |

Lost Revenue |

Limited Operation Visibility |

|

|

|

|

Real-World ExampleA pump unexpectedly fails, maintenance is out of inventory and the pump is out of service longer than expected. |

Real-World ExampleA pump in a remote area of the plant fails, emptying an entire tank of finished product on the floor without being noticed. |

Real-World ExampleA pump is unknowingly performing below expectations due to other system issues, but its not known until a process batch is complete and the final product is found to be outside of spec, requiring rework. |

Real-World ExampleA preventative maintenance plan exists for a plant to service pumps every 6 months, but some pumps have far more life and others still fail prematurely. |

Wilden SafeGuard SolutionWilden SafeGuard collects data of pump performance over time, including maintenance records, allowing the user to create robust preventative maintenance plans and anticipate need for replacement parts. |

Wilden SafeGuard SolutionReal-time monitoring and leak alert for immediate response, limiting product loss and potential cleanup costs. |

Wilden SafeGuard SolutionWilden SafeGuard makes it easy for the user to set alerts for pumps operating outside of the “normal” operating conditions. |

Wilden SafeGuard SolutionWilden SafeGuard provides unprecedented information about diaphragm life, allowing preventative maintenance plans to be more accurate and more efficient at protecting your people, product and process. |

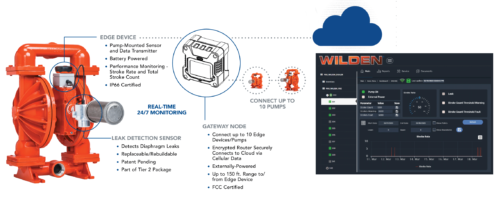

How it Works

Wilden SafeGuard is designed to monitor Wilden AODD pumps’ health and performance. It is composed of a single battery-powered sensor (Edge Device) mounted directly onto the pump which communicates to a sensor reader (Gateway Node). The Gateway Node, which can connect up to 10 Edge Devices/Pumps, operates as an encryption router, securely transmitting the data from all pumps to the Cloud. Once stored on the Cloud, real-time and historic operational information can be accessed by the user anywhere in the world through a secure smartphone app or an online portal.

|

Features and Benefits

The design and operation of the SafeGuard system allows for complete 24/7 real-time monitoring and alerts related to a number of critical performance parameters for the pump (diaphragms, balls, seats). These readings can show the user such things as:

- Leak detection to indicate diaphragm leaks and failures, preventing product loss and safety hazards

- Stroke rates to monitor changes to highlight performance abnormalities

- Stroke count for batching and setting maintenance schedules

- Real-time alerts via SMS or email to indicate any noteworthy change in operation that may be a precursor to pump or component failure

- Plug-and-play design for easy set up and easily retrofittable to current installations

- Maintenance records that can indicate patterns and help manage preventative maintenance plans

User Interface

Wilden AODD pumps’ health and performance is displayed and summarized on the Wilden SafeGuard User Interface service where you can view the status of your whole fleet of connected pumps down to the details of a single pump. Capabilities include:

- Fleet Management View

- Pump Dashboard

- Review Maintenance and Operation History

- Color Code Indicators of Status

- Customizable Parameters, Pump Naming, Users, and Alerts

Wilden SafeGuard System Options

| FEATURE | Tier 1 – Basic Package to Monitor Pump Performance | Tier 2 – Advanced Package Combining Pump Performance Monitoring & Real-Time Leak Detection |

|---|---|---|

| Edge Device | ♦ | ♦ |

| Gateway Node | ♦ | ♦ |

| Web UI and Phone App | ♦ | ♦ |

| Stroke Count | ♦ | ♦ |

| Stroke Rate | ♦ | ♦ |

| Leak Detection | ♦ | |

| 24/7 Real-Time Alerts | ♦ | ♦ |

| Abnormal Operation Alert | ♦ | ♦ |

| Pump Mounting Kit | End Cap | End Cap & Junction Box |