Case Study: Delivering double inspection advantages to world’s largest dairy group

Mike Edwards

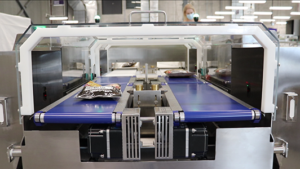

Features Fortress Technology metal detection QC quality control Fortress Technology installed this twin aperture Stealth metal detector and dual lane Raptor 200 checkweigher to integrate with a dual head VFFS bagging system for the world’s no.1 premium dairy producer.

Fortress Technology installed this twin aperture Stealth metal detector and dual lane Raptor 200 checkweigher to integrate with a dual head VFFS bagging system for the world’s no.1 premium dairy producer. In a space-saving product inspection breakthrough, Fortress Technology has custom-engineered a unique twin aperture Stealth metal detector and dual lane Raptor 200 checkweigher for one of the world’s leading, premium dairy companies.

Receiving shredded cheese pouches directly from a dual head bagger, the bold design unlocks substantial space and cost savings for the busy North American dairy plant.

Offering a customized solution that no other food inspection company could come close to in performance attributes, the twin lane conveyor configuration, consolidates a single metal detector uniquely divided into two apertures and two independent weight verification Raptor checkweighers for optimized quality control. Each technology and lane have its own air blast reject mechanism to isolate metal contaminants and weight rejects, helping to reduce and minimize good product being wasted by over 50 percent. Measuring 10 ft in length, Fortress also integrated a radius conveyor into the metal detector infeed.

For the producer of some of the world’s most iconic cheese brands, compromising on metal detection sensitivity was not an option. Explaining the benefits of the multi-aperture metal detector concept Fortress Technology spokesperson Eric Garr expands: “Compared to the alternative multi-lane contaminant detection and combination systems on the market, the high-spec Fortress multi-aperture system was engineered specifically to ensure that that there was no trade-off in terms of performance and metal detection sensitivity. One of the key benefits of a twin aperture system is the halving of waste caused by rejects.”

The special dual-lane version of Fortress Technology’s multi-aperture metal detector comprises a single unit split into two smaller dedicated apertures for each lane that act as independent metal detectors. For optimal metal detection sensitivity, the two compact apertures — measuring 102 mm/4in. high by 254 mm/10 in. wide — means that the packs pass individually right through the center point of the metal detector.

“With output per hour being the critical productivity benchmark, this game-changing multi-aperture design facilitates high speed and accurate metal detection and marks a step change for lean manufacturers seeking to reduce factory footprint and improve Total Cost of Ownership (TCO),” notes Garr.

Multiple advantages

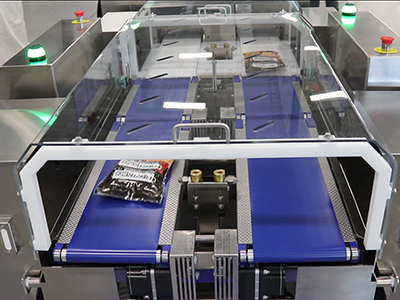

Fully integrated with the dairy plants’ upstream and downstream equipment and matching the 120 to 140 ppm output speed of the dual head VFFS bagging system, the compact geometry of the customized radius conveyor facilitates the positioning and orientation of product packs as they smoothly round the corner towards the metal detector. Providing optimal spacing between product packs as they are presented to each metal detector aperture helps to avoid congestion, bottlenecks and flexible packaging formats overlapping which could lead to sensitive weight verification checks being distorted.

As each lane is programmed to run independently, the bespoke design helps to minimize interruption to the packing process during product switchovers or if one lane stops working or requires maintenance. Additionally, the unique design gives the plant extra inspection and weight verification capacity, as two different product lines, pack sizes or SKUs can be run simultaneously adjacent to each other.

Air blast nozzles located between the two outfeed conveyors efficiently and independently remove contaminated product into lockable reject bins equipped with reject confirmation and bin full sensors. “For lighter weight packaged applications like shredded cheese, an air blast reject is the most efficient and has fewer moving parts. Contaminated products are instantly removed off the conveyor belt without disrupting production,” states Garr. With heavier products, Fortress would typically suggest using a pusher or retracting belt mechanism.

A rapturous reception

Using compatible collective parts, the inaugural integration of the new Raptor 200 Checkweigher marks another big milestone for the inspection specialist which recently celebrated its 25th anniversary. Delivering dynamic weight monitoring with minimal customizations to existing product feed and packing lines, the hygienic dual lane design also targets operational inefficiencies, notably upstream product giveaway, non-conforming food packs and packaging waste.

The rising cost of real estate in North American production facilities is pushing demand for space-optimized machinery. Image: iStockcredit@leezsnow

Garr expands: “The level of control this integrated Raptor digital checkweighing system gives versus batch checks on a fixed scale means the savings in reduced giveaway, especially on premium dairy products, is very quick.”

In milliseconds two packs pass over two Raptor load cells to weigh, analyze, capture and report data simultaneously. For ease of integration, air blast nozzles reject out of weight specification products with minimal operative intervention.

To ensure absolute traceability and compliance with retailer Codes of Practice and QA protocols, both the metal detector and Raptor checkweigher capture easy to read live OEE data. “By gathering live production information from each lane independently, the dairy group is able to establish the operational parameters and extract statistics most valuable to their business, for instance volume, weight, inspection speed, rejects or downtime,” adds Garr.

Equipped with Contact Reporter software, the dairy plant has the facility to export and convert time-stamped production data from their dual-aperture metal detector and integrate into readable formats aligned to their existing quality control reporting system.

Fortress also offers the option to connect the checkweigher to its Contact 4.0 connectivity software. Auditor-friendly, data reports are exported as either PDF or Excel files covering a specific production line and/or time period. “Rather than monitoring machine performance manually,” notes Garr, “this level of cohesive reporting on a multi-lane system provides valuable upstream trend feedback to boost operational efficiencies.”

Constructed to the highest food grade standards, the modular 200 mm wide conveyor assembly, conveyor decks and belts are all designed to be easily removed from the machine for rapid deep sanitation and maintenance. Operatives simply unclip and disconnect the conveyor motor. In just seconds, the conveyor belt is removed, and the belt tension and tracking is instantly restored when clipped back into place. All without using a single tool

Shrinking footprints

With rent per square foot in North American industrial manufacturing plants currently averaging US$6.36, this latest multi-lane combination metal detection and checkweighing innovation showcases the space-saving possibilities emphasizes Garr.

“Footprint is a top criteria and consideration for many of our customers today. For this particular dual lane dairy application,” he states, “we were tasked with engineering a system that integrated seamlessly with a fast-running dual head VFFS packaging machine. Through intelligent configuration of the conveyor and reject mechanisms, we succeeded in delivering a compact combination system without sacrificing the exceptional metal detection performance that Fortress always strives to deliver.”

This article was contributed by Toronto-based Fortress Technology.

Print this page