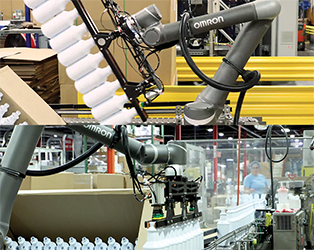

Collaborative robot improves handling of plastic containers

Mike Edwards

Features Omron Automation Schoeneck Containers application

Schoeneck Containers application A manufacturer of plastic containers for diverse consumer and commercial markets was seeking a collaborative robotic solution to overcome the pressures it was facing due to skilled labour shortages.

Founded in 1972, Schoeneck Containers (SCI) is a family-owned, family-operated company based in New Berlin, WI, that manufactures plastic containers for diverse consumer and commercial markets throughout the world. The company prides itself on its ability to provide innovative packaging solutions for its customers, as well as on its strong culture and state-of-the-art technology.

SCI strives to be perceived as a leader when its customers face packaging-related problems in their applications. In order to be a go-to partner that consistently delivers workable solutions for a challenging market, the company relies heavily on member engagement and highly advanced technologies.

Due to a labor shortage that is affecting the majority of manufacturers today, SCI began considering a collaborative robotic solution to augment the capabilities of its team. In the process of working on automation integration with Sure Controls, an industrial equipment distributor and system integrator in Greenville, WI, SCI became aware of the Omron TM Collaborative Robot and did some research on the product in addition to what it learned from Sure Controls.

Sure Controls clearly articulated all the benefits of the collaborative robot, and SCI decided that Omron’s technology would be a good solution for its application needs. Omron stepped in to assist with risk assessments and extra training to ensure that the new technology was implemented smoothly. Omron also discussed several potential automation options for SCI’s future applications.

Based on market demands, SCI came to the conclusion that one of the major challenges it needed to address for the near future was the widespread labour shortage felt throughout the manufacturing industry. With extremely low unemployment rates, the current environment made it even more difficult to find qualified operators to fill crucial roles.

The technical team at Sure Controls performed a deep-dive evaluation of various products to determine the right technology for SCI to take to its customers. The two companies analyzed a number of different products on the market and considered the robots’ technical specifications and the overall portfolio of products of each automation solution provider.

Omron’s strong product portfolio, which includes a full robotic line as well as safety and other integration solutions, was a major factor in SCI’s decision. The company was impressed with Omron’s ability to bring the entire solution together with robust technical support that covered all of SCI’s needs.

For SCI, the Omron TM Collaborative Robot’s integrated vision was a key differentiator because it enabled the company to re-deploy the robot more quickly and easily for initial applications and future deployments. The built-in vision solution along with 3D positioning allows the robot to orient itself within its environment and intelligently respond to changes in production requirements. It can also interact with machines with the efficiency of a human operator.

Watch video of the SCI application

In addition, SCI placed importance on higher payloads and longer reach, which Omron’s technology was able to accommodate. The robot’s fast and simple programming combined with advanced collaborative control was also a major advantage, as these capabilities fit in quite well with what SCI was trying to achieve.

SCI appreciated Omron’s large technology offering and the fact that all of its products are designed to function as part of comprehensive, end-to-end solutions. This gives SCI the ability to re-deploy existing technologies or introduce new products on the verge of coming available in the automation world.

SCI was able to get the Omron TM Collaborative Robot up and running within a day, and the technology allowed the company to deliver a much more flexible solution for its customers. The robot is also highly re-deployable, so SCI can easily move it from one line to another whenever necessary.

In its off-line label application, SCI was able to use the collaborative robot to achieve higher consistency and reliability and gain the ability to set the pace of production to fit with complex scheduling needs. The company no longer needs to worry about having to shut its lines down due to labour inconsistencies.

SCI has seen its customer satisfaction improve considerably, and it has also worked with Omron and Sure Controls to ensure that everyone has a thorough understanding of how the collaborative robot works and how to make the most of its capabilities. SCI considers this project to be a major success and looks forward to working with Sure Controls and Omron on various applications in the future.

This customer case study was contributed by Omron Automation.

Print this page