White paper: Dust collection challenges in continuous manufacturing processes

Mike Edwards

Features Camfil dust collection white paper

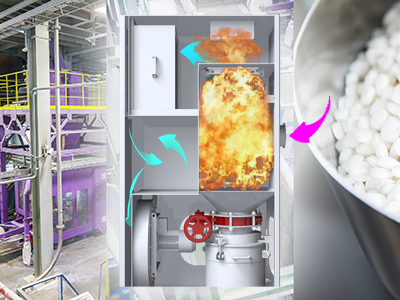

As product manufacturing methods change, dust collectors and other essential process equipment must evolve to meet new demands. For decades, the pharmaceutical and chemical industries have manufactured products based on batch production.

With this method, a predetermined weight of ingredients is processed before being discharged as finished product.

The more modern alternative is a continuous manufacturing process, which runs by simultaneously charging and discharging ingredients and finished product. This change in manufacturing process has been embraced by a number of major companies that consider it to be an improvement in production.

The key benefits of continuous manufacturing processes are the ability to have smaller processing equipment and facilities, simplified processes, and superior product quality control. However, these benefits can only be achieved if the auxilliary equipment is able to keep up. Uninterrupted dust collection is a critical consideration.

Download here to continue reading and receive this white paper by David Steil, Pharmaceutical Market Manager, Camfil Air Pollution Control.

Print this page