Gold mine dewatering problem overcome with AODD pumps

Mike Edwards

Features AODD John Brooks pumps video Wilden Wilden Brahma AODD pump

Wilden Brahma AODD pump Specifying the proper pumps in mine dewatering applications is critical to avoiding stalling and loss of production. In this example, a company was using 2-inch air-operated double-diaphragm pumps (AODDs) for its mine dewatering application at their gold mine site.

The solid content in the water was causing the ball check valves not to seat, this hold-up caused the pump to stall out which halted production.

Barry Norrish, a John Brooks Company mining application expert met with the customer to investigate the challenges it was having. The investigation determined that the ball check pump that was being used could not handle some solids larger than 1 in.

Video demonstration of how a Wilden AODD pump works

Norrish recommended the T810, a 2 in. Wilden Brahma flapper pump that can pass 2 in. solids, use less parts, and since the flapper opens and closes like a door, reduced wear.

The result for the gold mine was improved uptime and reduced service and maintenance costs.

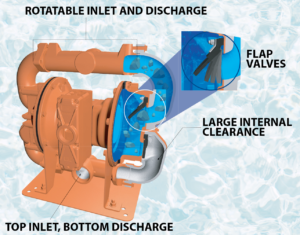

The pump performed its job properly due to its design:

The pump performed its job properly due to its design:

- Rotatable inlet and discharge to help meet application requirements — 3 positions at 90° — available in threaded or flanged connections;

- The AODD pump has flap valves to help handle large solids up to 3″ (76 mm); and

- Wetted path with large internal clearance to further help handle compressible solids up to 3 in. (76 mm).

In addition, the Brahma Series is designed for top inlet and bottom discharge, pushing solids directly out, protecting the pump when solids settle. The pumps can also handle suction lifts up to 25.0 ft. (7.6 m) Dry and 30.6 ft. (9.3 m) Wet.

This application story was contributed by John Brooks Company Ltd.

Print this page