Michelin Group and Pyrowave join forces for plastic waste recycling technology

Mike Edwards

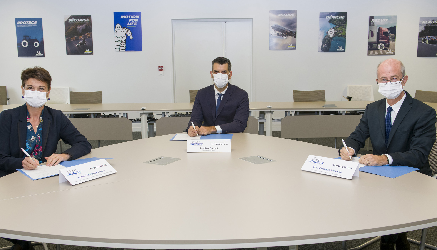

News plastics Signature of the Pyrowave-Michelin partnership: Sonia Artinian-Fredou, EVP, Services & Solutions, High Tech Materials Member of the Group Executive Committee at the Michelin Group, Jocelyn Doucet co-founder and CEO of Pyrowave, and Eric Philippe Vinesse, EVP, R&D — Member of the Group Executive Committee. (CNW Group/Pyrowave)

Signature of the Pyrowave-Michelin partnership: Sonia Artinian-Fredou, EVP, Services & Solutions, High Tech Materials Member of the Group Executive Committee at the Michelin Group, Jocelyn Doucet co-founder and CEO of Pyrowave, and Eric Philippe Vinesse, EVP, R&D — Member of the Group Executive Committee. (CNW Group/Pyrowave) Montreal-based Pyrowave has announced a joint development agreement with the Michelin Group of Clermont-Ferrand, France. Through the Pyrowave–developed technology, it is possible to generate recycled styrene from plastics found in packaging, insulation panels and/or household appliances, the company says.

The recycled styrene is a monomer used in the production of polystyrene and synthetic rubber for tires and a large number of consumer products.

The scientific breakthrough behind Pyrowave technology helps recycle plastics using microwaves. Unlike current thermal processes, the technology enables the recycling of plastic waste into high-quality raw materials using electricity — the energy form currently said to provide the highest decarbonation potential. It also provides higher yields, while being more accurate than conventional technologies, to replace virgin raw materials from oil and gas.

The joint development agreement between Pyrowave and Michelin will result in the possibility of redesigning new packaging or manufacturing new products from recycled plastics in the automotive, electronics or tire sectors.

The two companies will work together in the coming months to fast–track the industrialization of Pyrowave technology with a view to a certification and commercial roll-out in international markets. The joint development agreement, which will ultimately account for an investment of more than €20 million and combines Pyrowave’s expertise with Michelin’s industrial know-how.

In order to fast–track the validation of the technology and the certification of its products, Michelin’s technical teams will work with their Pyrowave’s counterparts to develop an industrial demonstrator, funded and operated by Michelin, by 2023. The technology will meet the highest standards in place within the group in terms of safety, operation and performance.

After a year of evaluation, Michelin was able to see the process in operation and test samples of recycled styrene in the composition of its tires. This polymer regeneration process is fully in line with Michelin Group’s strategic vision and its product sustainability objectives.

Print this page