ArcelorMittal, Government of Canada announce $1.765 billion investment in decarbonization technologies

Mike Edwards

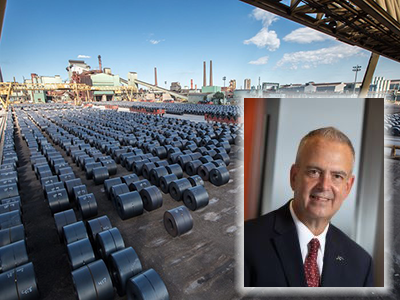

News decarbonization Government of Canada investment ArcelorMittal Dofasco president and CEO Ron Bedard (inset) said: “The new steelmaking footprint will improve our capability to support the most demanding product segments."

ArcelorMittal Dofasco president and CEO Ron Bedard (inset) said: “The new steelmaking footprint will improve our capability to support the most demanding product segments." ArcelorMittal has announced with the Government of Canada its intention for a $1.765 billion investment in decarbonization technologies at ArcelorMittal Dofasco’s plant in Hamilton, ON. The intended investments will reduce annual CO2 emissions at ArcelorMittal’s Hamilton operations by approximately 3 million tonnes, which represents approximately 60 percent of emissions, within the next seven years.

This means the Hamilton plant will transition away from the blast furnace-basic oxygen furnace steelmaking production route to the Direct Reduced Iron (DRI) – Electric Arc Furnace (EAF) production route, which carries a significantly lower carbon footprint.

ArcelorMittal says it will introduce new manufacturing processes that contribute to a considerable reduction of CO2 emissions and deliver other positive environmental impacts including the elimination of emissions and flaring from coke making and ironmaking operations.

The investment is contingent on support from the governments of Canada and Ontario. The Government of Canada announced it will invest $400 million in the project. The Company is in discussions with the Government of Ontario regarding its support.

At the heart of the plan is a 2 million tonne capacity DRI facility and an EAF facility capable of producing 2.4 million tonnes of high-quality steel through its existing secondary metallurgy and secondary casting facilities. Modification of the existing EAF facility and continuous casters will also be undertaken to align productivity, quality and energy capabilities between all assets in the new footprint.

The new DRI and EAF will be in production before the end of 2028.

This new production route for ArcelorMittal Dofasco will provide a technically advanced manufacturing environment for operations, maintenance, and technology staff to work in, with improved health and safety. New positions, training, and development will be provided for employees moving from existing business units to new assets, with approximately 160,000 training hours required to transition our workforce to the new footprint.

Highlighting the transformative impact of the announcement, ArcelorMittal Dofasco president and CEO Ron Bedard said: “The new steelmaking footprint will improve our capability to support the most demanding product segments with advanced high strength steels, including those used for the emerging electric vehicles in the automotive sector.

“The new steelmaking stream also sustains well-paying skilled positions in advanced manufacturing in Ontario, with the opportunity for our highly skilled employees to work in the most technically advanced Steelmaking assets in North America.

“The company’s bayfront property has been re-imagined and we are well on the way to a significant and broad reduction in environmental impacts, contributing to the health and sustainability of our community, the environment and the economy.”

ArcelorMittal has an ambition to be a net zero carbon emitter by 2050.

Print this page