Tutorial: Causes, effects & remediation techniques of air in liquid piping systems

Mike Edwards

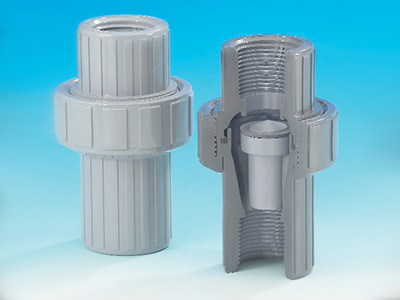

Features The Plast-O-Matic ARV Series Air Release Valves is designed to expel large volume of air at system start up, then close bubble tight.

The Plast-O-Matic ARV Series Air Release Valves is designed to expel large volume of air at system start up, then close bubble tight. There are three causes for air to be present in liquid piping systems. First, it is there to begin with. Unless the piping system is entirely assembled in a vacuum chamber, it will naturally have atmospheric air.

Filling the system will expel some of the air, but not all of it. Traces of the original start-up air remains trapped at high points in the system.

The second source of air enters mechanically. Air is fed in by pumps, drawn in through open valves, etc. And when the system has vacuum conditions, air sneaks through seals, leaks — any opportunity it can find. As Aristotle said, nature abhors a vacuum.

A third way air enters a system is by piggybacking on the liquid itself. In the average municipal water system, for example, entrained air represents about 2% of the total water volume. This air is then released through natural outgassing and joins the rest of the air in the system’s high points.

To show just how much air this is, if the entrained air in a 100-foot pipeline were to completely settle out of the liquid, it would represent a 2 ft slug of air. Whether the 100 ft pipe has a ½ or 3 in. diameter, 2% still represents a 2 ft slug.

Now if it were 1,000 feet of piping, you could conceivably have a 20 ft foot slug of air! Add that to the pre-existing air, plus whatever entered through pumping, and you have the potential for a serious volume of air.

So, there are pockets of air in the system… what’s the problem?

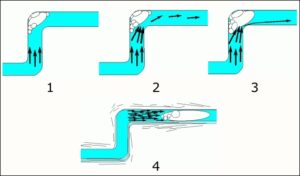

Air in a piping system tends to accumulate at high points during low flow or static conditions. As the flow rate increases the air can be forced along the pipeline by moving liquid, and may become lodged at extreme high points, where it reduces the area available for flow. These flow restrictions reduce the efficiency and performance of the system.

1. Air (or gas) in a liquid piping system tends to accumulate at elbows and high points during low flow or static conditions.

2. This air pocket impedes flow as the system operates.

3. The flow restriction reduces the efficiency and performance of the system, forcing the pump to work harder and line pressure to fluctuate.

4. Eventually the air pocket grows, pressure builds, and the air pocket is set in motion with potentially devastating impact.

As an air pocket grows, the velocity moving past that point increases until eventually the air is swept on toward an outlet. While line restrictions are a problem, a more serious situation can occur when air is rapidly vented from the system under pressure. The result is similar to instantaneous valve closure: water hammer will occur, with pressure surges that can easily exceed the strength of the system.

This often results in damage to the system, to property, and it can be dangerous to personnel.

How to get rid of it

One of the time-honoured methods of releasing system air is to connect a long vertical run of open pipe to a ball valve on a tee. Open the valve at system start up to allow air to escape, then close it as the pipe fills.

Air/vacuum valves are also used on tanks for the same purpose. If you look at enough piping systems, you’ll find a combination of valves and do-it-yourself remedies installed to rid the lines of air.

The solution – as you probably know by now — is an air release valve.

The Plast-O-Matic Series ARV (shown in the diagram below) will automatically vent air during start-up of the system. Series ARV is normally open, and air is expelled as the system pressurizes. As the liquid rises, the self-guided poppet closes and ultimately seals bubble tight. When the system is shut down and liquid level drops, the valve re-opens.

A further safeguard is to use a degassing valve, Series DGV, which releases trace amounts of air as the system is operational. In many applications, both the air release and the degassing function are required. For these situations it is recommended to use both valves, or a single combination valve such as Series CARD.

A further safeguard is to use a degassing valve, Series DGV, which releases trace amounts of air as the system is operational. In many applications, both the air release and the degassing function are required. For these situations it is recommended to use both valves, or a single combination valve such as Series CARD.

For more information on system air remediation, please click here.

Print this page